Blog

As much innovation as the printed circuit board assembly industry seems to see, some things stay the same. What are some areas in which client chorusing have remained the same over the years? More layers, better signal integrity and different materials.

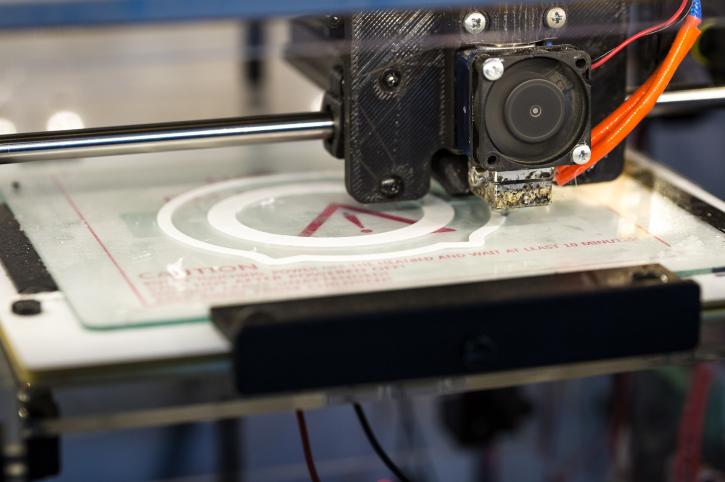

3D printing, or additive manufacturing, holds some very exciting innovation in printed circuit board assembly design and manufacturing; but the technology is not accurate enough to use for professional applications, yet.

Perhaps one technology that has not made quite the inroads that had been expected from industry and clients is 3D printing (or additive manufacturing) of printed circuit board assembly.

Think only a few years back and 3D printing was designated the next big disruptor in printed circuit board assembly manufacturing. In fact, there were predictions that 3D printing would enable user-end printed circuit board assembly. Those predictions were, even at that time ignorant of the facility of mass production and testing, however, it is a surprise that additive manufacturing has not revolutionized manufacturing processes for industrial printed circuit board assembly. After all, 3D printing should appease many of the demands listed at the very beginning.

So why has the reality of 3D printing fallen behind the expectation that had preceded it; we take a look.

Complexity

3D printing has grown not only in capability, but also in the range of materials with which it can work. However, the complexity of creating complex conductive traces requires consistency and accuracy which is yet to be perfected.

Low-resolution

Printer resolution (typically referring to the ‘Z’ axis layer height) has been getting higher ever since the development of the first commercial 3D printers, but it is as much a factor of printer capability as it is the material used. The combination of printer capability and material has not proven sufficient for professional printed circuit board assembly just yet.

Material

Professional users of printed circuit board assembly are extremely demanding of the signal integrity. Which is why PCB makers rely only on the best materials. With 3D printing this is not a viable solution as the material must be conducive for additive manufacturing – a compromise which places restrictions on its conductivity.

3D printing is an extremely exciting technology for printed circuit board assembly. The possibility of being able to create 3-dimensionally configured traces and boards has the possibility of changing PCB design and form-factor altogether.

However, the realities of mass production and quality testing (all motivated by ensuring the highest yields and quality for clients) mean that 3D printing must mature quite some way before it can be integrated as a true production process.